OUR LOGO – WMW – IS RECOGNIZED FOR DECADES OF EXPERIENCE IN MACHINE TOOLS MANUFACTURING

WORLD MACHINERY WORKS products are sold worldwide, to a broad array of customers, including those in the United States, Canada, Mexico, France, Belgium, Germany, Italy, England, Norway, Sweden, Denmark, Finland, Turkey, Russia, India, China, South Korea, Australia and elsewhere. Our goal is to deliver the products and services you need in a reliable, responsible, and professional manner that sets a new standard for the industry. Our customers appreciate our products for reliability and ease in operation and maintenance.

Where special features are required for specialized applications, our skilled and experienced Engineering Department will assist in determining and implementing required design modifications, providing our customers with the flexibility they need to handle their specific manufacturing challenges. Our dedication to quality is backed up by comprehensive warranty protection on all of our products and quick and responsive customer service.

IMPORTANT YEARS IN THE HISTORY OF WORLD MACHINERY WORKS

- 2000

- 2000

- 2008

- 2010

- 2013

- 2015

-

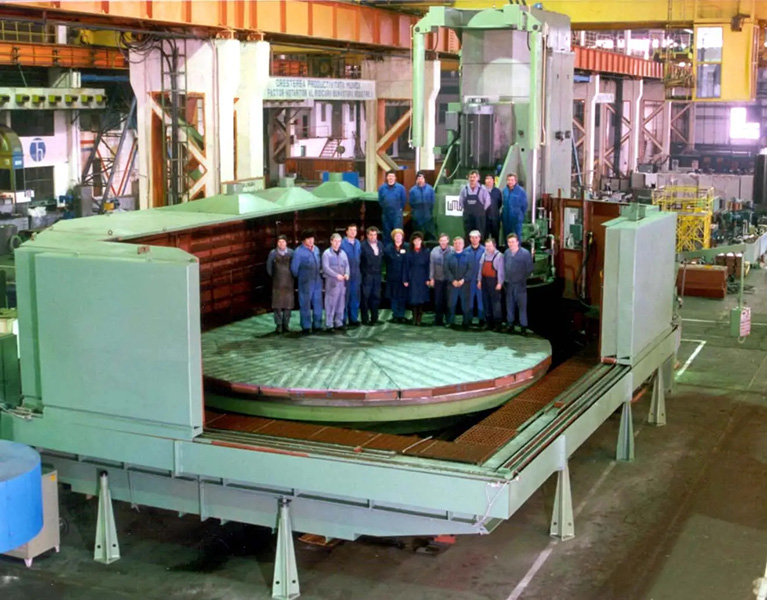

RPVR 6700 surface grinder is manufactured the largest of its kind in the world, a special order from SCHAFFER Grinding Company, USA, which bought over 30 surface grinders over the time.

-

Company participates in important international exhibitions in USA (IMTS, Chicago), Germany the largest of its kind in the world, a special orderMETAV, Düsseldorf), China (CIMES & CMTF, Beijing), Italy (EMO Milano), and India (IMTF Delhi, Mumbai)

-

A group of five machines is delivered to VSMPO company in Russia for the machining of the Boeing and Airbus landing gear made out of titanium alloy.

-

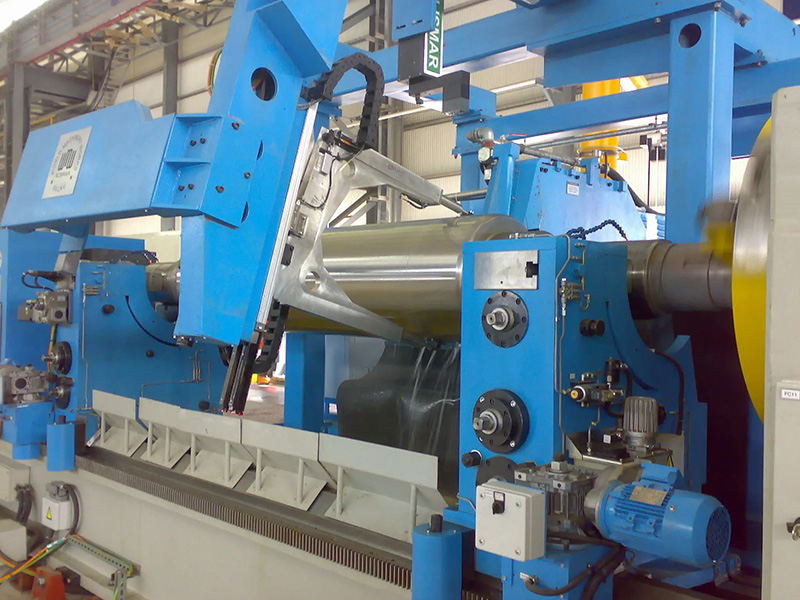

Inauguration of one group of three roll grinders delivered to Salem Steel Plant branch of the Steel Authority of India

-

Manufacture and delivery of 4 horizontal boring and millingmachines model BMK 130 CNC to BHEL Hyderabad, India in collaboration with HMT India

-

Manufacture and delivery of a complex roll grinding machine model RGC 1400 X 5000 CNC to USS POSCO USA

OUR CAPABILITIES

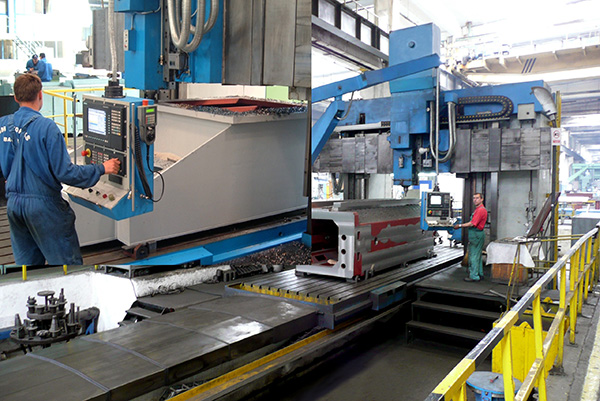

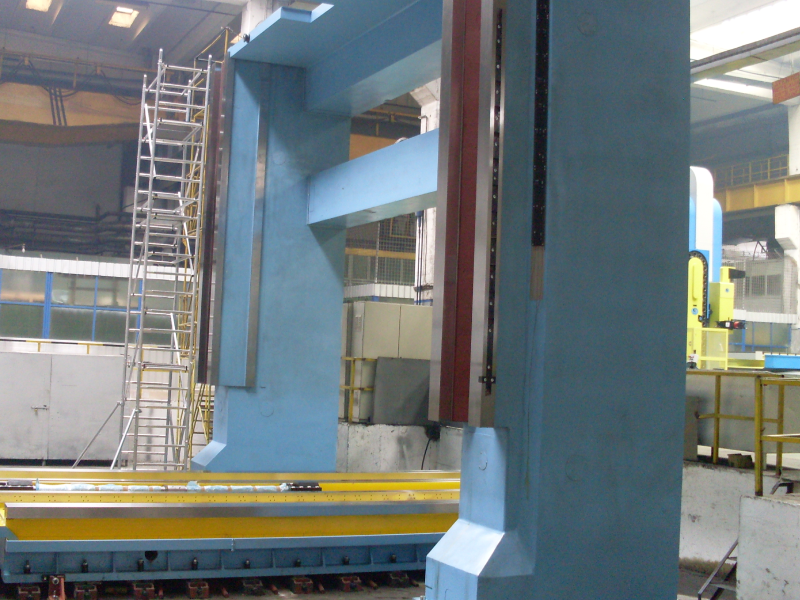

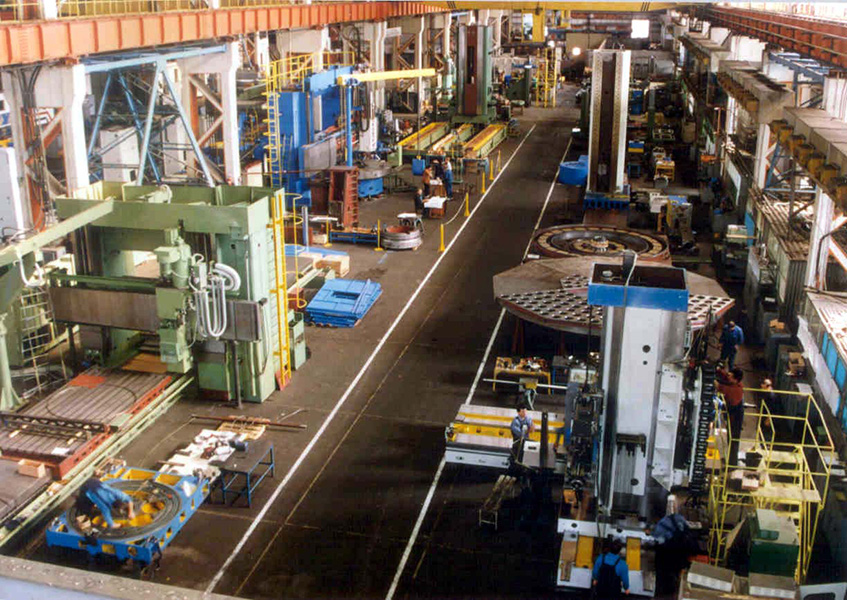

Our modern production facility includes manufacturing, warehouse and office spaces. Workshops are equipped with large capacity, universal and heavy-duty machines, capable to complete in-house component machining, sheet metal work etc. Our capabilities include machining of parts up to 12 000 mm long, 3 000 mm wide and 2 000 mm high. The 40 ton heavy-duty cranes and high ceilings facilitate the manufacture, assembly and testing of all our machines, which include some of the largest and most complex machine tools manufactured and in use today.

IN - HOUSE MACHINING

“BRIDGE TYPE GRINDING MACHINE, MODEL SZ 12.000 Travels: Table: 12 000 mm Grinding head on the cross rail : 2 800 mm Cross rail (vertically): 2 000 mm Machining accuracy 0.010 mm / m.”

“BRIDGE TYPE MILLING MACHINE, MODEL FLP 2200 CNC CNC control SIEMENS Sinumerik 840D Travels: Table: 9 000 mm Milling head on the cross rail: 2 500 mm Cross rail (vertically): 2 150 mm ”

“BORING AND MILLING MACHINE VHN 13 CNC Machining dimensions: 2000x1500x2000 mm.”

HORIZONTAL LATHE SP 1000 X 6000 CNC

IN - HOUSE ASSEMBLING & TESTING

R&D AND DESIGN

“Research-Development and Design is a very important department in our company. Through the research and development process, our specialists within the Technical Department develop new technologies in the production of machine tools. Technical Department is able to solve technical problems locally and remotely, offering technical assistance to our customers. The design and production of machine tools is a key point on which WMW relies. The design and development of the most complex mechanical, hydraulic and electrical projects is offered by our specialists, who are fully dedicated, collaborating with the client to obtain a complex project.”

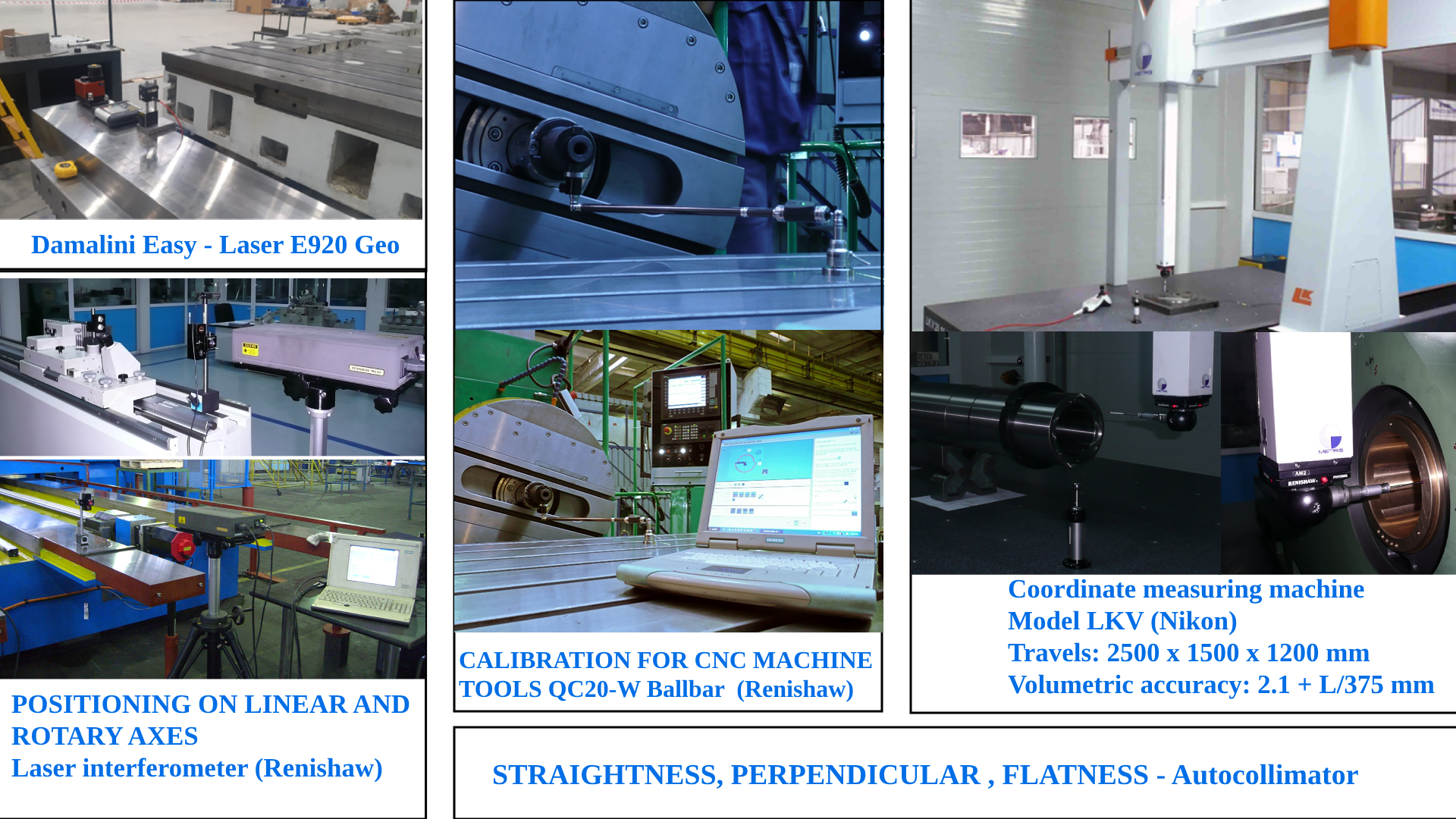

QUALITY ASSURANCE

Our department has measuring devices for measuring the geometry of the machine, and for measuring parts. Before a part is assembled, it is checked by our experts.Our customers’ loyalty attests to our quality, Quality assurance is a very important area of our company.

ISO 9001:2015 QUALITY SYSTEM

ISO 9001:2015 QUALITY SYSTEM