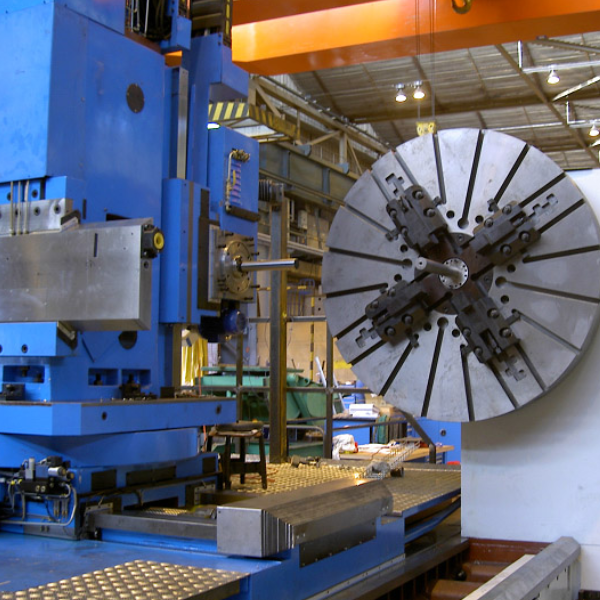

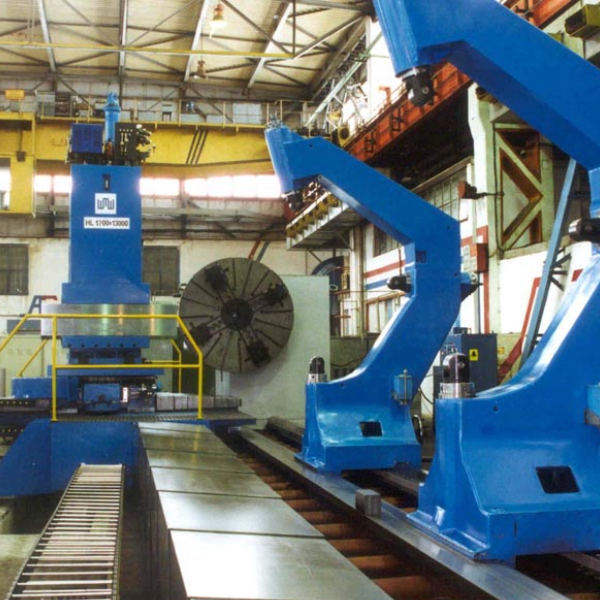

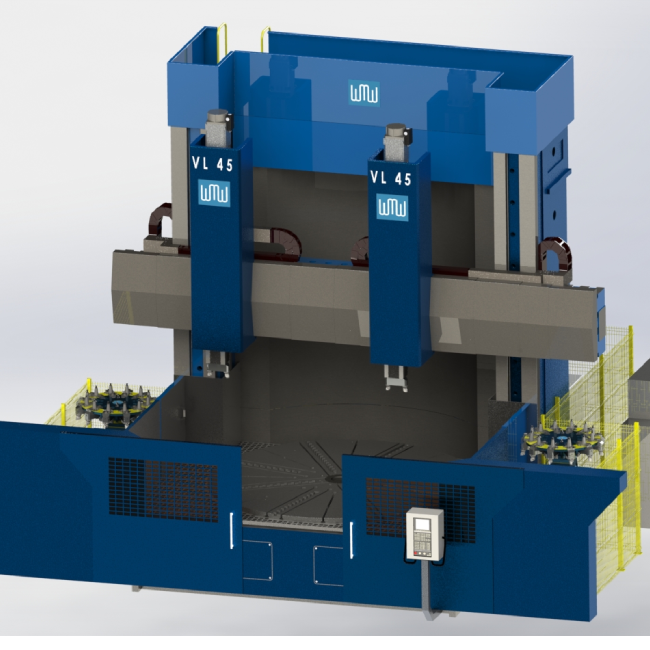

- Heavy and robust structure

- Maximum rigidity during heaviest cutting operations

- High accuracy in finishing operations

- Excellent surface finish

- Cast iron bed with 3 / 4 guideways

- Hardened and ground guideways (steel inserts)

- Counterways lined with anti-friction material

- HEIDENHAIN measuring system

- Automatic lubrication system

- REXROTH/PARKER/ATOS hydraulic components

- SIEMENS / FANUC / FAGOR AC servo motors, PLC and electrics

- SIEMENS /FANUC / FAGOR CNC Systems

- Telescopic steel covers for the bed and cross slide guideways

TRAVELS:

- X-axis – cross slide

- Z-axis – saddle

- Steady rests (open and closed type)

- Turret type tool system (with 12 tools)

- Milling device

- Grinding device

- Chip conveyor

Technical specifications

| HL 1000 | HL 1300 | HL 1700 | HDL 2200 | HDL 2700 | ||||

| Chuck diameter [mm] | 1000 | 1 300 | 1 700 | 2 200 | 2 700 | |||

| Max. swing over bed guides [mm] | 1 300 | 1 600 | 2 000 | 2 500 | 3 000 | |||

| Max swing over cross slide [mm] | 1 000 | 1 300 | 1 700 | 2 200 | 2 700 | |||

| Distance between centres [mm] | 3 000 – 10 000 | 4 000 – 12 000 | 4 000 – 14 000 | 4 000 – 16 000 | 4 000 – 16 000 | |||

| Max. workpiece weight (on steady rests) [kg] | 30 000 | 30 000 | 30 000 | 80 000 | 80 000 | |||

| Spindle speed [rpm] | 1 – 7 00 | 1 – 7 00 | 1 – 5 00 | 1 – 375 | 1 – 250 | |||

| Spindle motor power [kW] | 60 | 60 | 60 | 100 | 100 | |||

| X-axis travel [mm] | 650 | 800 | 1 000 | 1 250 | 1 500 | |||

| Tailstock quill travel [mm] | 250 | 250 | 300 | 300 | 300 | |||

| Feeds X / Z [mm / min] | 1 – 10 000 / 1 – 5 000 | 1 – 10 000 / 1 – 5 000 | 1 – 10 000 / 1 – 5 000 | 1 – 10 000 / 1 – 5 000 | 1 – 10 000 / 1 – 5 000 | |||